This week I am working with the rest of the students in the Fab Lab to create a machine of some sort. We finally decided that we wanted to do something unique and fun, not just a 3d printer or cnc machine of some sort. We thought a unique machine could create something edible which would make it fun and new. Our finaly decision was a pancake printer that would make fun, edible designs. |

Due to my experience using Solidworks I, along with another classmate Sam was assigned to do the extruder design for the project. My main brainstorming challenge ended up being what type of extruder to use to accuratly extrude a viscous material. |

My first design used a worm gear extrusion system to extrude two different types/colors of pancake batter. This system seemed ideal at first but had two flaws. There was no viable way to ensure gravity did not push batter out when the worms were not spinning and second we only had one stepper motor to use for the extrusion system and therefor we could not have a dual extruder using this design. |

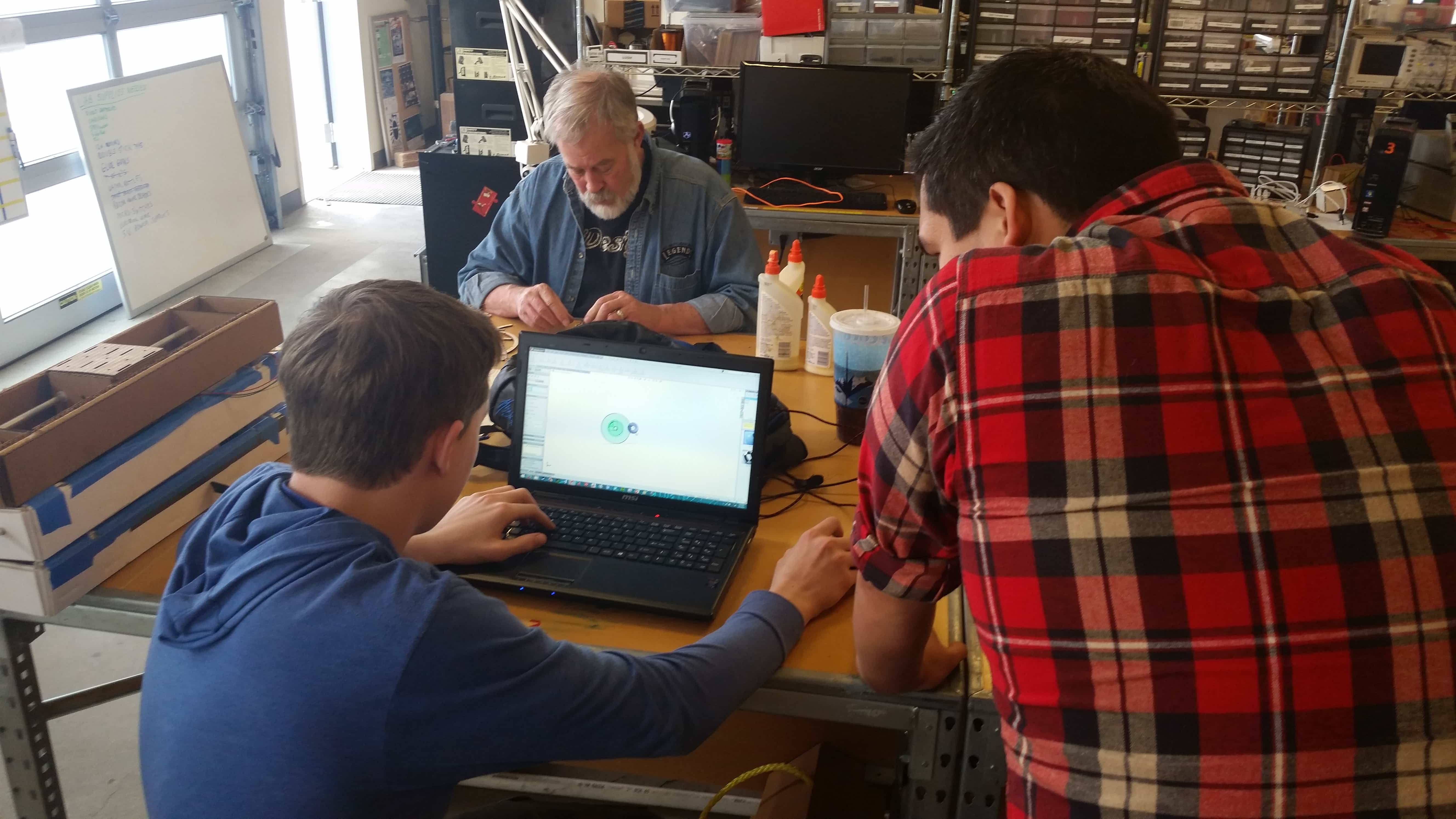

To create a more realiable extrusion system I did some research. I found that progressive cavity pumps, also known as moineau pumps are a very effective method for creating an extruder or pump for viscous liquid. There was little to no information online on designing such a pump so I had to start from scratch in Solidworks to try to design such a pump. After much trial and error here is what I found. Start with the size of shaft you want for the interior of your pump(in grey above) use this to extrude a helix of the desired length, making sure to define the pitch. Next create the stator or housing(green in above photo). Extrude a cylinder and make a slot in one end that had the same with as the diameter of your rotor, and double the high of your rotor. Use another helix of the same length, but DOUBLE the pitch to create an extruded cut. The rotor will fit inside of this cut and form a progressive cavity pump. You can use the shell command in Solidworks to make is look pretty just like in the picture above. |

With my prototype progressive cavity pump printed and tested it was time to move onto my final design. I increased the diameter of the rotor and housing to work for pancake batter and added mounting for a stepper motor using simple joints so as the rotor moved left to right while spinning it would not break because a centered stepper motor is driving it. I also added mounting holes for the stepper motor and an hole in the side of the assemble for the pancake batter to feed into. |

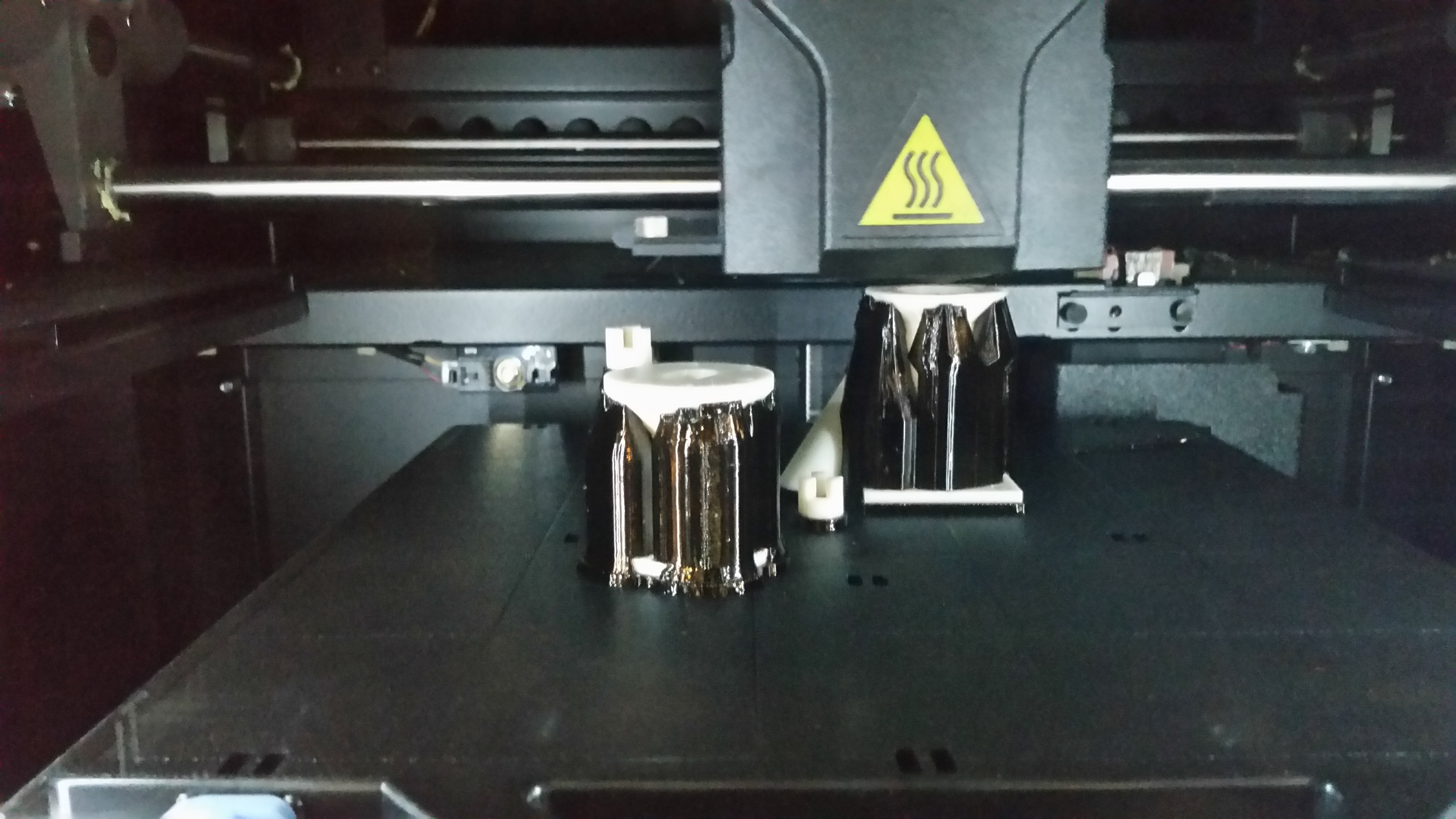

Finally once my design was complete is was time to print all of the parts and assemble them for the machine. |

In the end the machine was a success. We were able to successfully print pancakes the resembled the shapes we had designed. The pancake batter extruder that I designed and built was also a success. It was able to move batter with a decent consistancy and did not jam or break during the tests. That being said, it was not perfect, when the extruder stopped some batter would still leak out and onto the grittle, and when starting up again there would be a delay between the motor starting to spin and batter being extruded from the end of the extruder. In the future this could be compensated for with adjustments to the G-code or a redesign of the extruder itself, possibly adding a seal at the nozzle to keep batter from leaking. |